The Ultimate Guide To Premier Aluminum Llc

Table of ContentsAll about Premier Aluminum LlcExcitement About Premier Aluminum LlcThe Main Principles Of Premier Aluminum Llc Some Known Factual Statements About Premier Aluminum Llc

(https://premieraluminum.wordpress.com/2024/12/12/premier-aluminum-llc-your-trusted-aluminum-casting-company/)Utilizing low price and unqualified vendors can create high quality issues, and threw away time and money in the long run. To assist you with the procedure, here are some points to take into consideration when picking the ideal steel casting distributor.

A firm that only utilizes the investment casting procedure will certainly attempt to offer you on why that procedure is best for your application (Aluminum Casting). But suppose using the sand spreading procedure is best for you and your demands? Instead, search for a vendor that offers a range of casting procedures so the very best alternative for YOU is selected

If dealing with a single source for every one of your casting needs is necessary to you, the distributor needs to be varied in its abilities. When integrated with various other incorporated capabilities, this can help streamline and compress the supply base. When picking the appropriate casting supplier, cautious consideration ought to be provided to top quality, solution, and cost.

See This Report on Premier Aluminum Llc

Purchasers significantly pick casting suppliers who have machining capacities. This can avoid conflict if problems are uncovered throughout machining. If a 3rd party is machining, it may result in "finger-pointing" regarding who is at fault. Is it a casting problem or a machining problem? If the spreading provider uncovers a problem throughout machining, the trouble is dealt with quicker with no disagreement over whose fault it is.

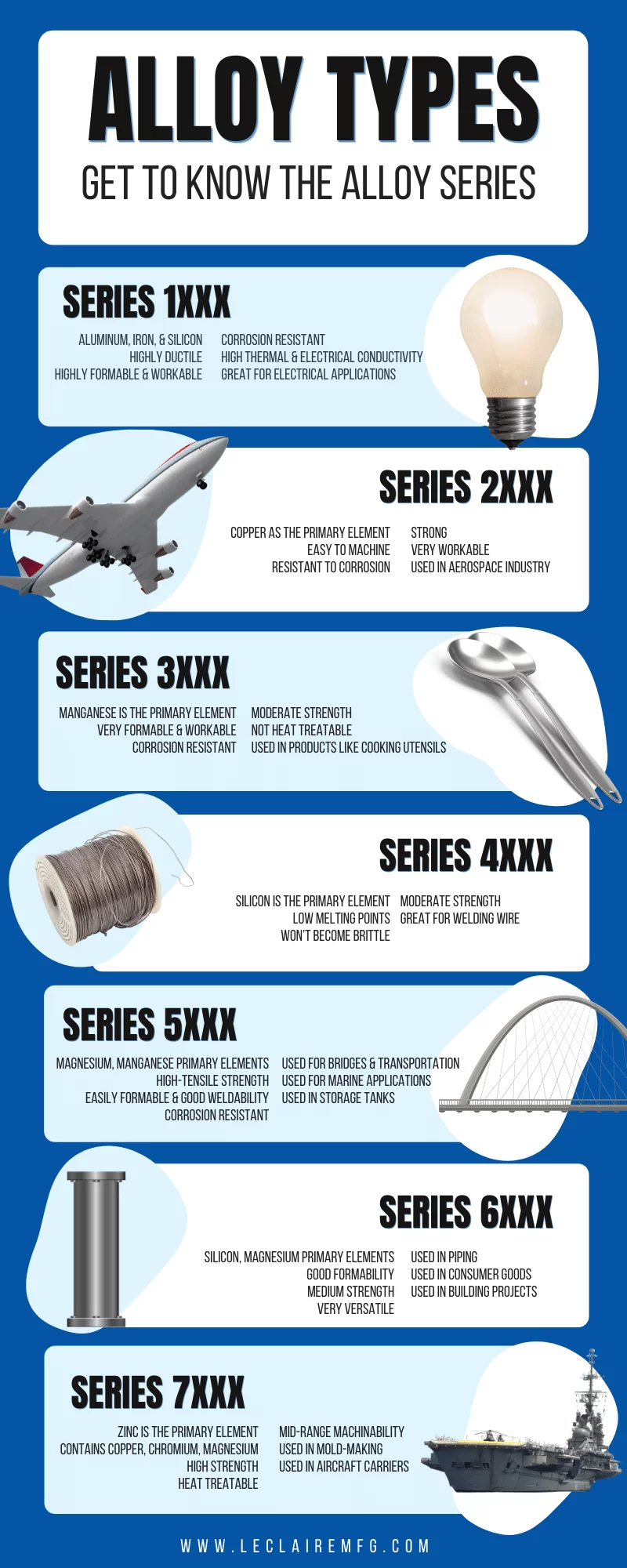

Issue or no, incorporated machining simplifies the supply chain and decreases taking care of time and shipping cost prior to the item makes it to the client. What do you need from your casting distributor? Are you looking for someone to simply supply a metal component to your front door or do you require a lot more? For example, if you do not have in-house metallurgy competence, validate that the vendor can offer assistance in picking the appropriate alloy based upon your certain application - Foundries in Wisconsin.

Some factories are limited or specialized. Make sure the supplier can fulfill all your material or alloy needs to get rid of the requirement for multiple suppliers.

All about Premier Aluminum Llc

Research study the distributor's website. Talk to a sales associate or service affiliate.

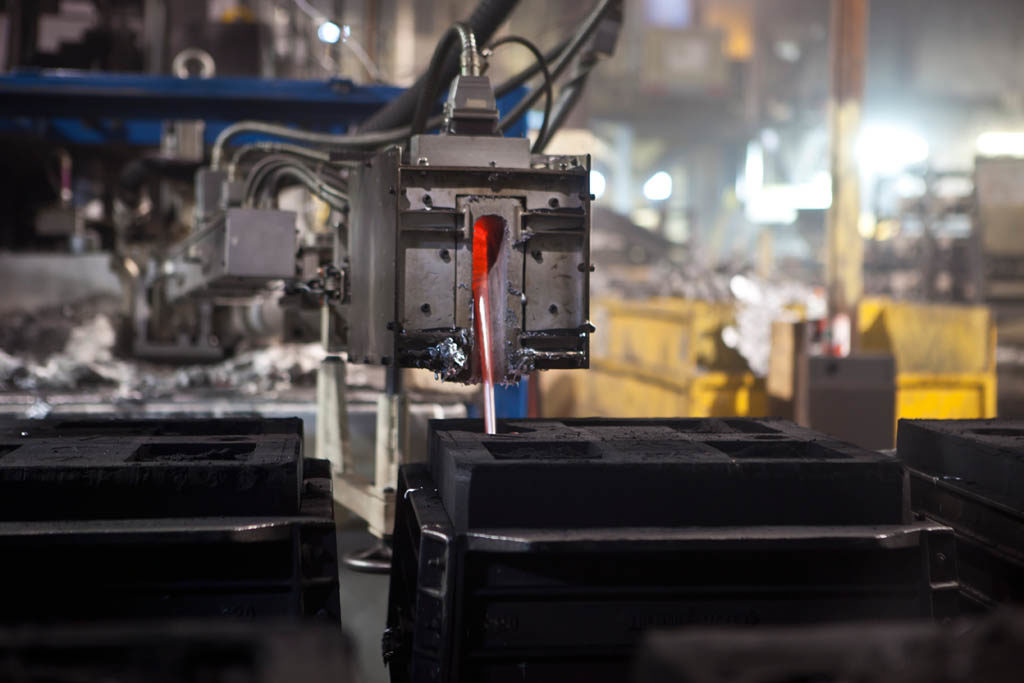

Light weight aluminum is likewise light-weight and has good corrosion resistance, making it suitable for applications where weight and longevity are necessary elements. In addition, light weight aluminum spreading is an economical technique of production, as it requires less power and sources than other approaches. Iron casting, on the various other hand, includes pouring molten iron right into a mold to develop a desired shape.

The Single Strategy To Use For Premier Aluminum Llc

Iron spreading is additionally able to withstand high temperatures, making it appropriate for use in applications such as engine components and commercial machinery. Iron casting can be extra pricey than aluminum casting due to the greater cost of raw materials and the power anchor required to thaw the iron. When deciding between aluminum spreading and iron casting, it is essential to think about the particular requirements of the application.

In conclusion, both aluminum spreading and iron casting have their very own one-of-a-kind benefits and disadvantages. There are 3 sub-processes that fall under the classification of die spreading: gravity pass away spreading (or permanent mold spreading), low-pressure die spreading and high-pressure die spreading. To obtain to the finished item, there are three primary alloys utilized as die spreading product to pick from: zinc, aluminum and magnesium.